Description

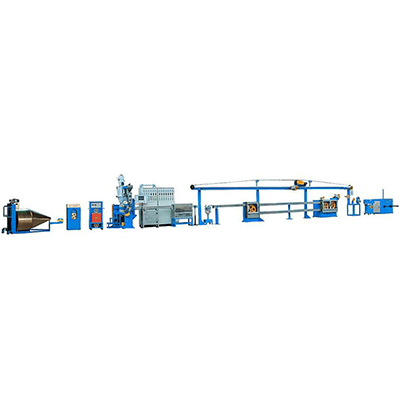

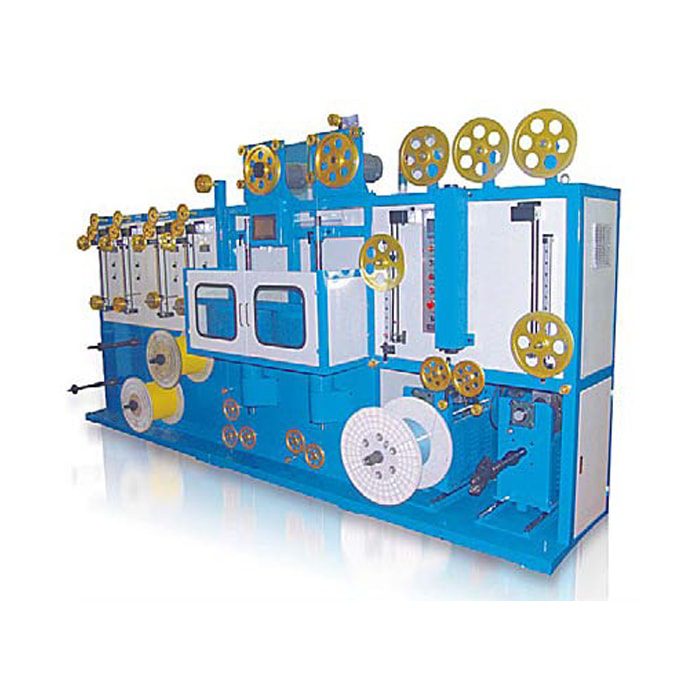

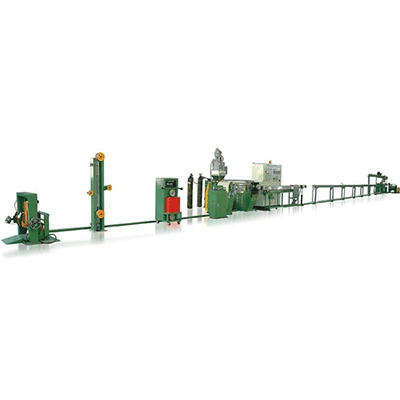

The PRV-FI-WE Series Thin Insulation Extruder is specially designed for high-speed processing of international standard AVS and AVSS automotive wires, along with a wide range of low-voltage and irradiated cable types. This series offers exceptional insulation accuracy with ±0.003mm diameter control, making it ideal for high-spec applications in the automotive and electronics industries.

With a maximum production speed of up to 800 meters per minute, the PRV-FI-WE series significantly boosts production efficiency while ensuring uniform insulation on wires ranging from AWG #28 to #12. Compatible materials include LSZH, PVC, PE, irradiation PVC, and irradiation polyolefins, covering all major insulation standards.

Key Features:

-

Compatible with AVS, AVSS, low-voltage audio/video, and PVC insulated wires

-

±0.003mm precision diameter control

-

Max. line speed up to 800 m/min

-

Handles electron-beam irradiated insulation materials

-

Ideal for automotive & instrumentation wire production

Technical Parameters

| Machine type | PRV-FI-WE-50+30 | PRV-FI-WE-60+40 |

|---|---|---|

| Application | Low Smoke Zero Halogen, PVC, PE, Irradiation PVC & Irradiation Polyolefin Materials | |

| Insulation wire | 0.5mm- 1.95mm (AWG#28-#12) | 0.5mm- .95mm(AWG#28-#12) |

| Max. conductor | 2.0mm | 2.0mm |

| Max insulation | 5.0mm | 5.0mm |

| Precise Diameter Control | ±0.003mm | ±0.003mm |

| Max. Speed | Max.500m/min | Max.800m/min |