Description

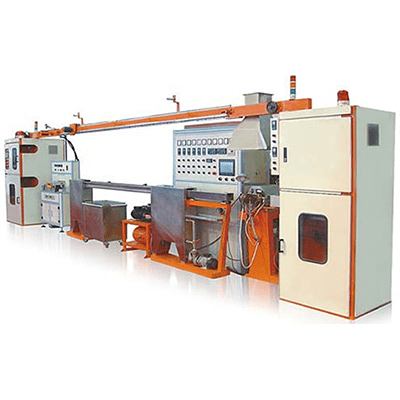

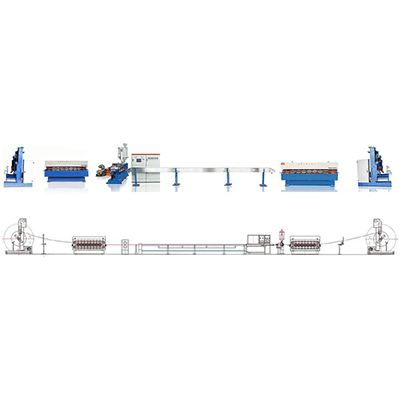

Parovi Machines offers a high-precision Teflon Extruder Line designed for the extrusion of FEP, PFA, and ETFE insulated wires used in high-temperature and critical applications. This Teflon Extrusion Line includes a tension-controlled pay-off system, pre-heater, high-performance extruder, hoist, cooling trough, haul-off, and take-up unit. Every element is engineered for consistent quality, ease of operation, and efficient production.

high-precision Teflon Extruder Line from Parovi Machines is Ideal for the manufacture of solar cables, automotive wires, robotics wiring, and communication cables, the Teflon Extruder Line ensures perfect insulation without degradation of material properties. With zone-based temperature control and advanced automation options, the system provides seamless operation and minimal waste.

Whether you’re scaling production or enhancing precision, our extrusion solution is tailored for long-term reliability, speed, and operational efficiency.

Technical Parameters

| MODEL | PRV-TEF-WE-40 | PRV-TEF-WE-50 | PRV-TEF- WE-60 |

|---|---|---|---|

| Screw diameter | Ø40 | Ø50 | Ø60 |

| LD Ratio | 25:1 | 25:1 | 25:1 |

| Temperature control | 6 Zone | 6 Zone | 7 Zone |

| Main machine power | 10HP | 15HP | 30HP |

| Extrusion capacity kg/hr | 15 | 25 | 45 |

| Conductor diameter (mm) | 0.1-3.0 | 0.2-6.0 | 3.0-28.0 |

| Insulation diameter (mm) | 0.3-4.0 | 0.4-8.0 | 4.0-32.0 |

Key Features:

-

Compatible with FEP, PFA, ETFE (Teflon family)

-

LD Ratio 25:1 for efficient material processing

-

Advanced 6 to 7 zone temperature control

-

Options in screw diameter: Ø40, Ø50, Ø60

-

User-friendly control interface

-

Stable haul-off and tension-controlled pay-off

-

Durable take-up and cooling system

-

High energy efficiency with powerful motors (10HP to 30HP)