Description

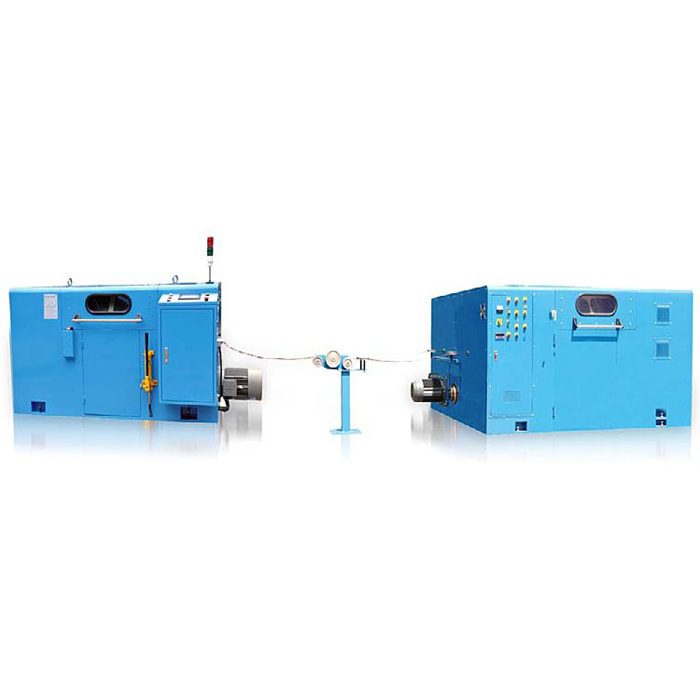

The PRV-ST Series High-Speed Single Twist Cantilever Buncher is expertly designed for the efficient twisting and bunching of a wide range of cables, including HDMI, data, bare copper, shielded multicore, and control cables. Equipped with a cantilever arm structure, Single Twist cantilever buncher combine high rotation speed, low inertia, and superior traverse functionality for uniform and consistent output.

Single Twist cantilever buncher available in four models — PRV-ST-630, ST-800, ST-1000, and ST-1250 — this series accommodates core diameters from 0.1mm to 5.0mm and delivers smooth, high-speed operation up to 800 RPM with advanced computer-controlled pitch adjustment.

Each Single Twist cantilever buncher features a single twist main system, active pay-off, central taping, and side longitudinal taping options, making them a versatile solution for modern cable manufacturing.

Key Features:

-

Cantilever design with low rotation inertia

-

Computer-controlled twisting pitch

-

Non-tension pulleys with high bending radius

-

Active pay-off and programmable taping setup

-

Side-way longitudinal taping and central taping included

-

Easy tray loading/unloading mechanism

-

Coiling box traverse with stepless pitch adjustment

-

Applications:

-

HDMI cable twisting

-

LAN and Ethernet cable laying

-

Multicore shielded power/control cable bunching

-

Bare copper wire and fine wire twisting

-

Data cable and high-frequency signal cable processing

-

Technical Parameters

| Machine Model | PRV-ST-630 | PRV-ST-800 | PRV-ST-1000 | PRV-ST-1250 |

|---|---|---|---|---|

| Core OD | Ф 0.5-Ф3.0mm | Ф 0.8-Ф3.0mm | Ф 0.1-Ф5.0mm | Ф 1.0-Ф5.0mm |

| Max Stranding OD | Ф 12mm | Ф 20mm | Ф 25mm | Ф 30mm |

| Traverse Pitch | 2-12mm | 3-20mm | 3-30mm | 3-35mm |

| Speed | Max800rpm | Max600rpm | Max500rpm | Max450rpm |

| Twisting Pitch | 20-200mm | 20-300mm | 20-400mm | 30-500mm |

| Pay-off Bobbin Size | Ф 500mm | Ф 500-Ф630mm | Ф 500-630mm | Ф 500-Ф630mm |

| Take-Up Bobbin Size | Ф 630mm | Ф 800mm | Ф 1000mm | Ф 1250mm |

Technical Parameters

| Machine Model | PRV-ST-630 | PRV-ST-800 | PRV-ST-1000 | PRV-ST-1250 |

|---|---|---|---|---|

| Core OD | Ф 0.5-Ф3.0mm | Ф 0.8-Ф3.0mm | Ф 0.1-Ф5.0mm | Ф 1.0-Ф5.0mm |

| Max Stranding OD | Ф 12mm | Ф 20mm | Ф 25mm | Ф 30mm |

| Traverse Pitch | 2-12mm | 3-20mm | 3-30mm | 3-35mm |

| Speed | Max800rpm | Max600rpm | Max500rpm | Max450rpm |

| Twisting Pitch | 20-200mm | 20-300mm | 20-400mm | 30-500mm |

| Pay-off Bobbin Size | Ф 500mm | Ф 500-Ф630mm | Ф 500-630mm | Ф 500-Ф630mm |

| Take-Up Bobbin Size | Ф 630mm | Ф 800mm | Ф 1000mm | Ф 1250mm |