| Application |

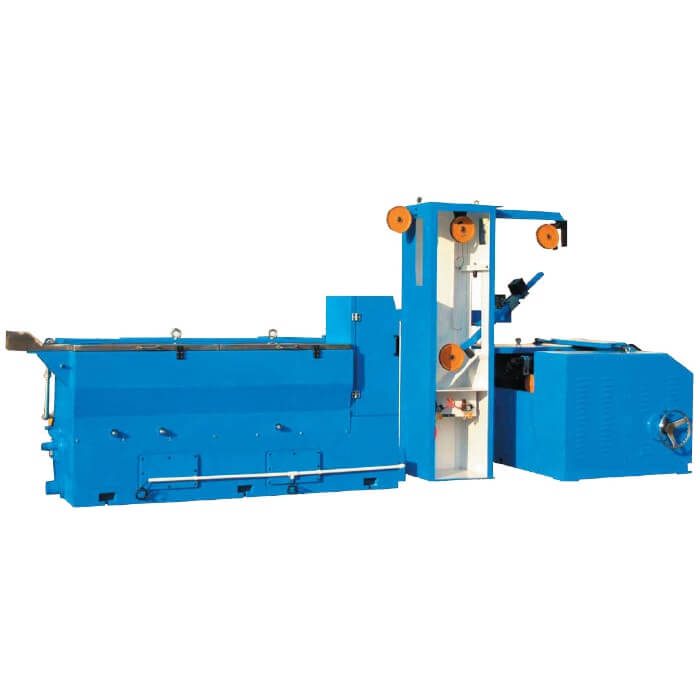

Annealing & Tinning of Copper Wire |

| Number Of Wires Processed |

40 |

| Wire To Processed |

0.08-0.32 mm |

| Max Wire Speed |

300 mts./min |

| Pay – Off |

Curl Flyer Or Constant Tension Pay-Off |

| Tinning Mode |

Single/ Double furnace hot dip with dies |

| Pay-off bobbin size |

Ø300 mm |

| Take-up Mode |

Single bobbin torque take-up |

| Take-up bobbin size |

PT10-PT25 |

| Installed Motion Power |

14kw |

| Installed Heating Power |

35kw |

| Total Installed Power |

49kw |

| Traversing Unit |

Casting Block Gear Traverse |

| Machine Dimension (LxWxH) |

20 x 1.6 x 2.2M |

| Gross Weight |

4500 kg |